How do you determine the cause of an electrical breakdown in the extruded cable core?

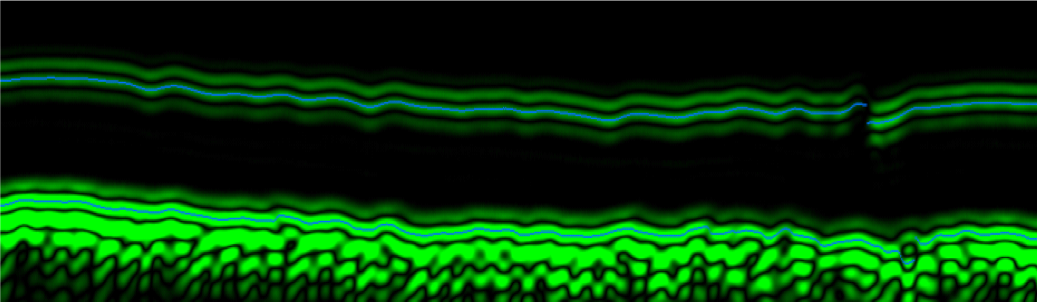

Here is the B scan of a cable which failed in electrical testing at the factory. As the data collected was time stamped and had recorded production length from PLC input data, Acuity were able to locate the fault site data very quickly. Note the sudden change of the tracking (blue) line at the right of the picture. This is actually the scan of the inner screen layer, with the conductor reflection below it (bright green layer).

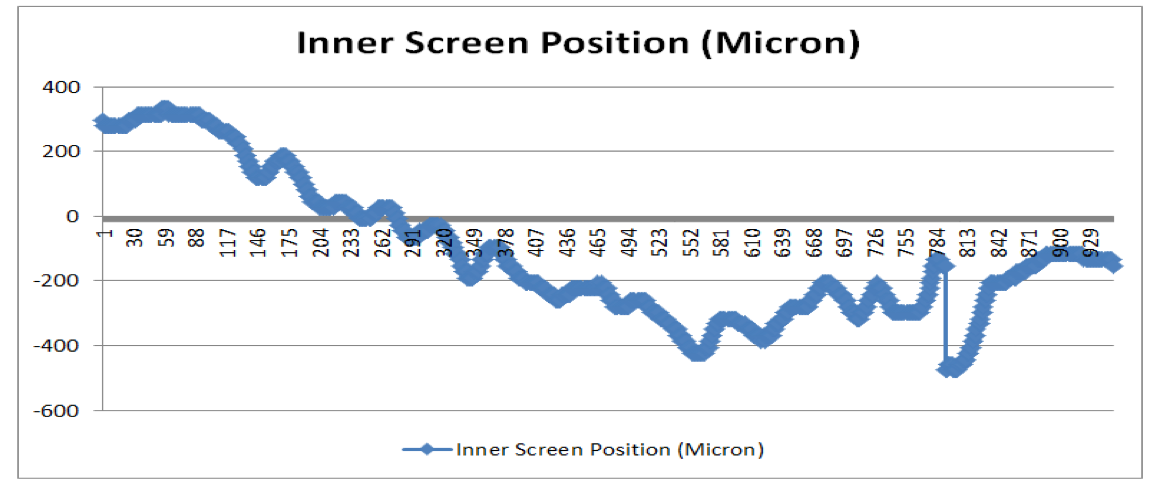

Acuity re-processed the raw data for the inner screen to discover that there was a rapid change in the inner screen position of around 400 microns. The graph shown is actual data captured by the UltraScreen during production.

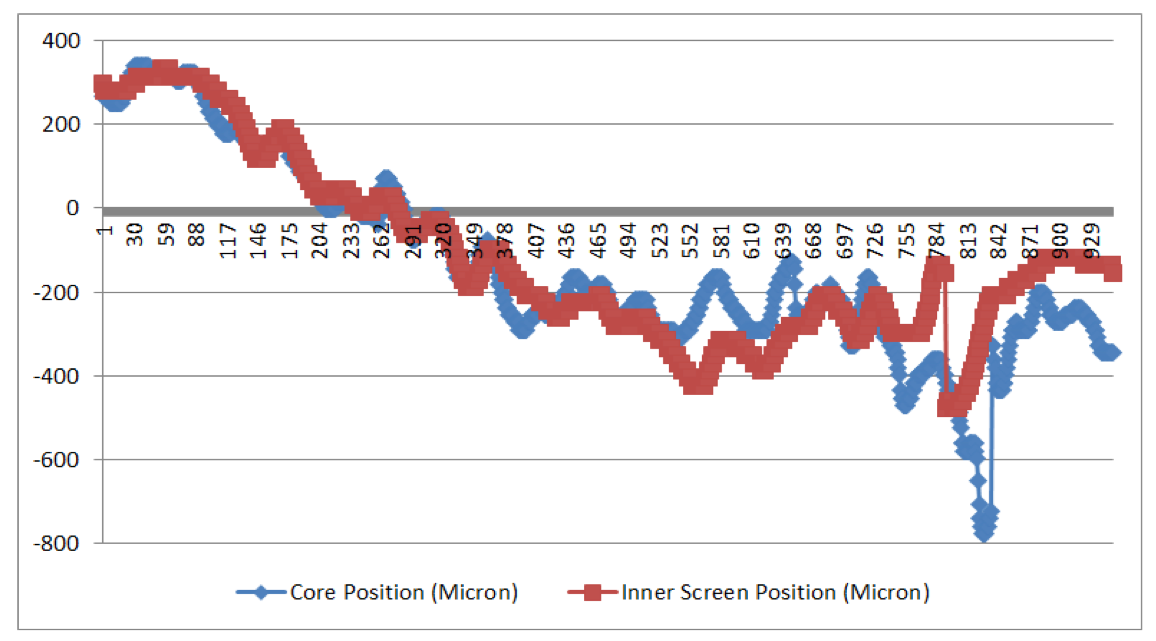

By aligning the data for the conductor surface with the inner screen layer position, it could be shown that the cause of the failure was due to a bad conductor winding, which the extruded inner screen followed.