Ultrasonic Vision for the Ultimate in Cable Quality

Ultrasound technology is widely used in medical imaging of course but the human body is relatively easy to scan - full of water with a variety of different materials to reflect energy, and in a static position so that multiple scans are possible to determine the smallest features inside the body.

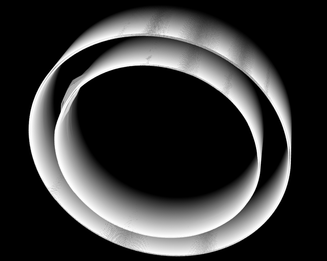

On the other hand, cross linked polyethylene absorbs ultrasound energy. A moving power cable being extruded on the production line at more than one metre per minute makes the detection of extremely small features normally difficult to extract from the high noise background. Acuity's engineers spent many years in the sonar world, where detection of 'foreign objects' was vital to the submarine's stealth operations and survival. Many of the techniques used to detect and record such 'abnormalities' have been designed into our products where the lowest false alarm rates mean an amazingly accurate level of real detections and the greatest confidence in the system. Typically, a 10 day production run of HV cable might generate only one or two alarms during that period.

On the other hand, cross linked polyethylene absorbs ultrasound energy. A moving power cable being extruded on the production line at more than one metre per minute makes the detection of extremely small features normally difficult to extract from the high noise background. Acuity's engineers spent many years in the sonar world, where detection of 'foreign objects' was vital to the submarine's stealth operations and survival. Many of the techniques used to detect and record such 'abnormalities' have been designed into our products where the lowest false alarm rates mean an amazingly accurate level of real detections and the greatest confidence in the system. Typically, a 10 day production run of HV cable might generate only one or two alarms during that period.

Our Team

Sales and Marketing - Tony Hepton : Tony has spent the majority of his working life in the marketing and sales of non contact instruments and sensors, mainly in the electrical parameter measurement market. Since obtaining his honours degree in Electrical & Electronic Engineering, Tony has always promoted new science & innovative technologies that bring new and highly accurate solutions to measurement problems.

Chief Technology Officer - Sean Connell : Sean joined Acuity in 2015 after finishing his degree, and has been highly innovative in introducing many new and improved software developments in the detection, recording and imaging of the internal features of the extruded cables and factory joints. His work in changing Acuity's systems to touch screen operation and listening to the end user (Operators) has vastly improved the system's ease of use which signifies Acuity's product range.

Software Development - Ben Pearson : Ben joined Acuity in 2020 after finishing his degree and has helped us to take forward the 3D animation of our scan data looking for features and issues with factory flexible joints using the UltraProfilor system.

We're Here for You 24/7

Acuity products aren't just a plug and play solution for the ultimate in cable quality assurance. With real-time monitoring Acuity can offer both additional analysis support, continuous software updates with increased features and the big data storage support you need to ensure continuous cable monitoring is effective for the whole team.