Ultrasound energy - the safest technology available

Unlike x-ray or other radiation technologies, ultrasound is inherently safe.

This is why it is used extensively in medical monitoring and diagnosis.

This is why it is used extensively in medical monitoring and diagnosis.

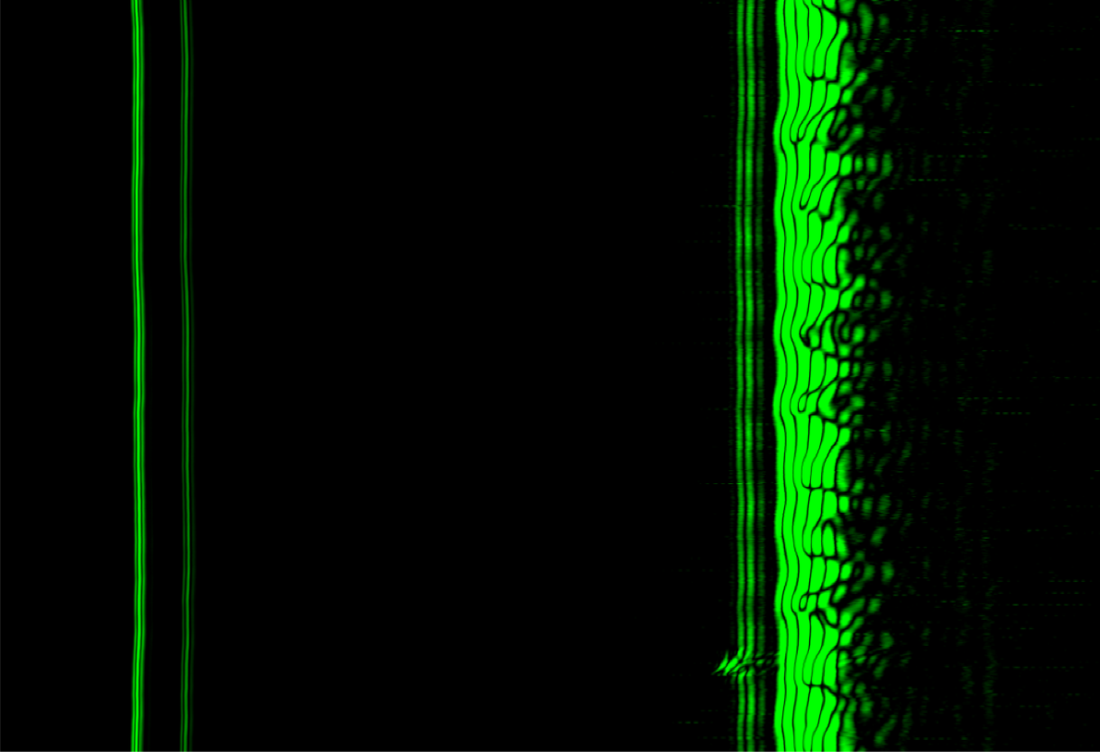

How it worksWhen an ultrasound wave crosses a material boundary where there is a difference in acoustic impedance (typically 1% in medical technology) some of the energy is reflected back to the transducer to be recorded and stored by the system. Air voids, metal particles and other materials can therefore be detected within the insulation layer of the cable.

|

AccuracyUsing high speed data acquisition electronics and the most modern processing hardware, cables are scanned along the whole length at intervals of 250um (at 1m/minute line speed).

Unlike slow averaging technologies used only for layer thickness measurement, this high level of scanning allows Acuity to detect rapid layer variations that normally lead to electrical breakdown failure. Online scan rates are dictated by production line speeds - typically 1m/min for HV cable. Offline scan rates of 0.1m/min are typically used for greater resolution during joint scanning. |

Ease to useAutomatic set up and detection of layers in 16 channels and internal features means that minimal operator effort is required to run the system. Large amounts of data are stored in an efficient manner and the system does not require manual intervention during a production run.

At the end of a run a fully automatic report highlighting the layer widths and the main features found is generated. |

Automatic detection of insulation inclusion

Engineering Perfection for the Perfect CableAcuity Ultrasonics has been researching the internal quality of EHV, HV and MV cables since 2009. During this time, many thousands of kilometres of extruded cable have been scanned in factories across Europe.

The high resolution scanning of factory made flexible joints is also possible using our offline tool UltraProfilor. |

Delivering Quality AssuranceElectronic records of every millimetre of cable produced can be stored, re-processed and re-examined to determine the optimum settings for feature detection. Every production line has a unique signature which can be seen in the scans recorded.

|

The New Industry StandardImproved standards follow new product developments.

Already operational at several major cable manufacturing sites Acuity Ultrasonics technology platforms have been proven to deliver quality assessment in cable production like no other. Completely non-contact our UltraScreen and UltraProfilor platforms offer complete assessment in cable production so you can deliver the highest assured quality of cable manufacturing to your customers. Who wants to settle for second best? Adopt ultrasound scanning of your cables to guarantee the total quality you produce and that your customers desire. |